Piston Air Compressors: Key Maintenance Factors

Piston (reciprocating) air compressors are known for their simple structure, ease of maintenance, and wide range of industrial applications. As one of the most commonly used compressor types, proper installation and regular upkeep are essential to ensure long-term efficiency, stable air quality, and reduced risk of unexpected failures.

SWAN Air Compressors summarizes these essentials from three perspectives: installation environment, routine maintenance, and periodic servicing, helping your equipment remain in optimal condition for years to come. By following these guidelines, users can minimize component wear, lower energy consumption, and avoid unexpected downtime.

1. Installation Environment

–Proper Ventilation

Air compressors generate significant heat during operation. If heat cannot be effectively dissipated, internal components may deteriorate more quickly, leading to reduced efficiency and shortened service life.

Ensure the installation area is well ventilated, with at least 30cm of clearance around the unit to allow for maintenance access and prevent discharged hot air from being recirculated back into the compressor.

– Mounting Location

Exposure to moisture and direct sunlight can damage electrical systems as well as plastic and rubber components. Compressors should be installed indoors or in a sheltered area. The foundation must be firm and level to minimize vibration and excessive noise during operation.

–Avoid Hazardous Environments

Dust, corrosive gases, flammable substances, and high humidity can severely impact compressor performance and safety. Dust may clog filters and reduce efficiency, while corrosive or flammable gases can cause equipment failure or even pose fire and explosion risks. These conditions should be avoided when selecting an installation site.

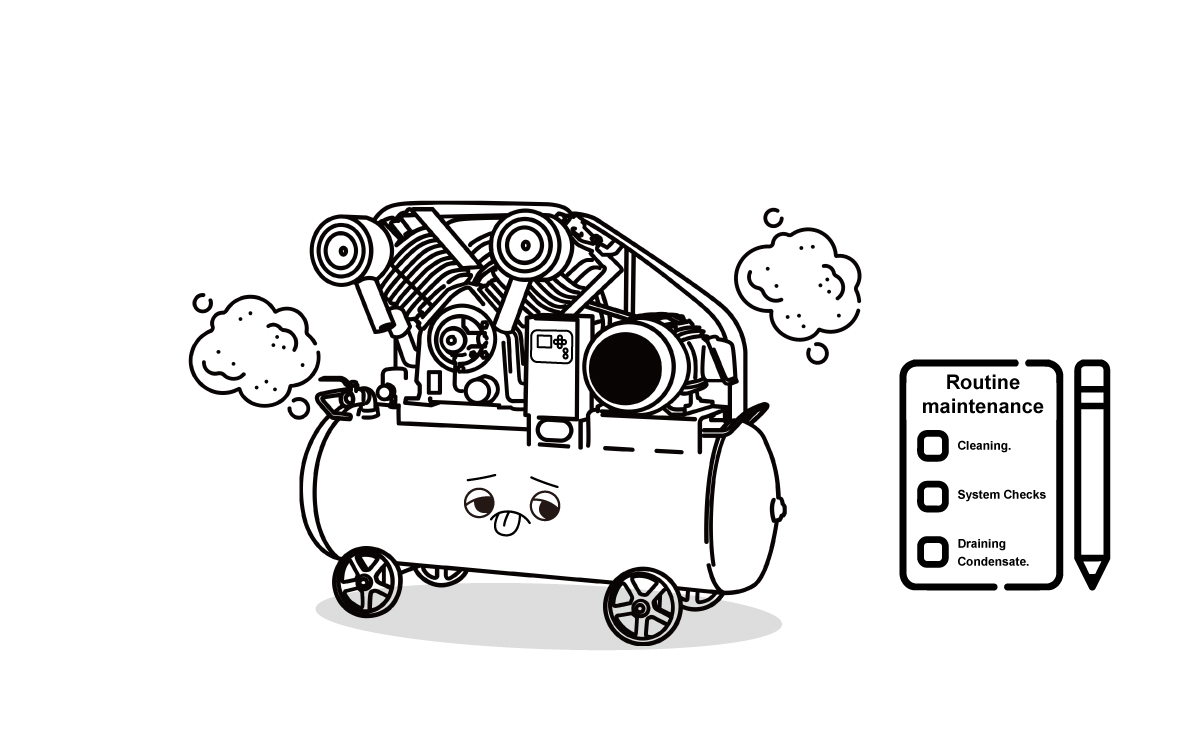

2. Routine Maintenance

– Cleaning

Routine cleaning applies not only to the compressor itself but also to the surrounding environment. Removing dust with an air gun or cloth helps maintain effective heat dissipation and allows early detection of issues such as loose components or aging material.

A clean environment also improves intake air quality and reduces the risk of foreign objects interfering with operation.

– Draining Condensate

Moisture naturally condenses during air compression and cooling, accumulating in the air receiver and piping. If not drained regularly, condensate can reduce air storage volume, cause internal corrosion, impair control components, and affect end-product quality.

Even when an automatic drain valve is installed, periodic inspection is recommended to ensure proper operation and prevent blockages or leakage.

– System Checks

Key components such as pressure switches and safety valves should be checked regularly. Electrical systems must be protected from insects or small animals that could cause malfunctions, short circuits, or fire hazards. The air treatment system also requires routine checks and replaces filter elements on schedule to maintain consistent air quality.

3. Periodic Service

–Lubricating Oil Management

• Always use dedicated compressor oil. Fully draining and replacing the oil approximately every six months or 1,200 operating hours, whichever comes first. Maintain the oil level within the specified range.

• Avoid mixing unknown oils or simply topping up without changing the oil, as this can lead to sludge formation, carbon buildup on valves, and accelerated cylinder wear.

• For heavy-duty models with forced lubrication systems, replace the oil filter whenever the oil is changed.

–Belt Tension Inspection

The drive belt plays a critical role in maintaining compression efficiency. A belt that is too loose may cause abnormal noise during startup and increase the risk of breakage due to repeated stress.

Inspect belt tension and wear at least once per month with power disconnected. Adjust tension as needed and replace worn belts immediately to prevent performance loss or unexpected downtime.

For additional guidance or professional support, SWAN Air Compressors is always ready to assist.

.jpg)