Although the initial purchase cost is higher, many people believe a variable frequency air compressor is more efficient and cost-effective than a fixed speed air compressor in the long run. However, that is not necessarily the correct assumption. For example, if an air compressor runs at the minimum load when the capacity is too big, or if an inverter is fully loaded with top speed when the capacity is too small, these incorrect configurations will only lead to minuscule power saving. Let's explore some solutions together.

Topic 1: Variable frequency air compressor = Power saving?

Let's understand how variable frequency air compressors save energy.

- The variable frequency air compressor adjusts the flow rate according to consumption to save energy use in the unloading mode.

- Saving the energy consumption of pressure increases from target pressure to unloading pressure.

- Saving the energy in loading mode during soft starts.

- Optimize power consumption and environment cooling to reduce related equipment consumption.

Then, why is energy saving not as expected?

1. Choose the wrong air compressor

-Capacity under demand: the inverter is fully loaded at top speed all times; the total input energy consumption is higher due to the inverter's self-consumption.

-Capacity over demand: the minimum loading rate is still higher than the air demand, causing the machine to idle.

2. System or control limitation

-Narrow pipe and excess leakage

-Incorrect pressure setting

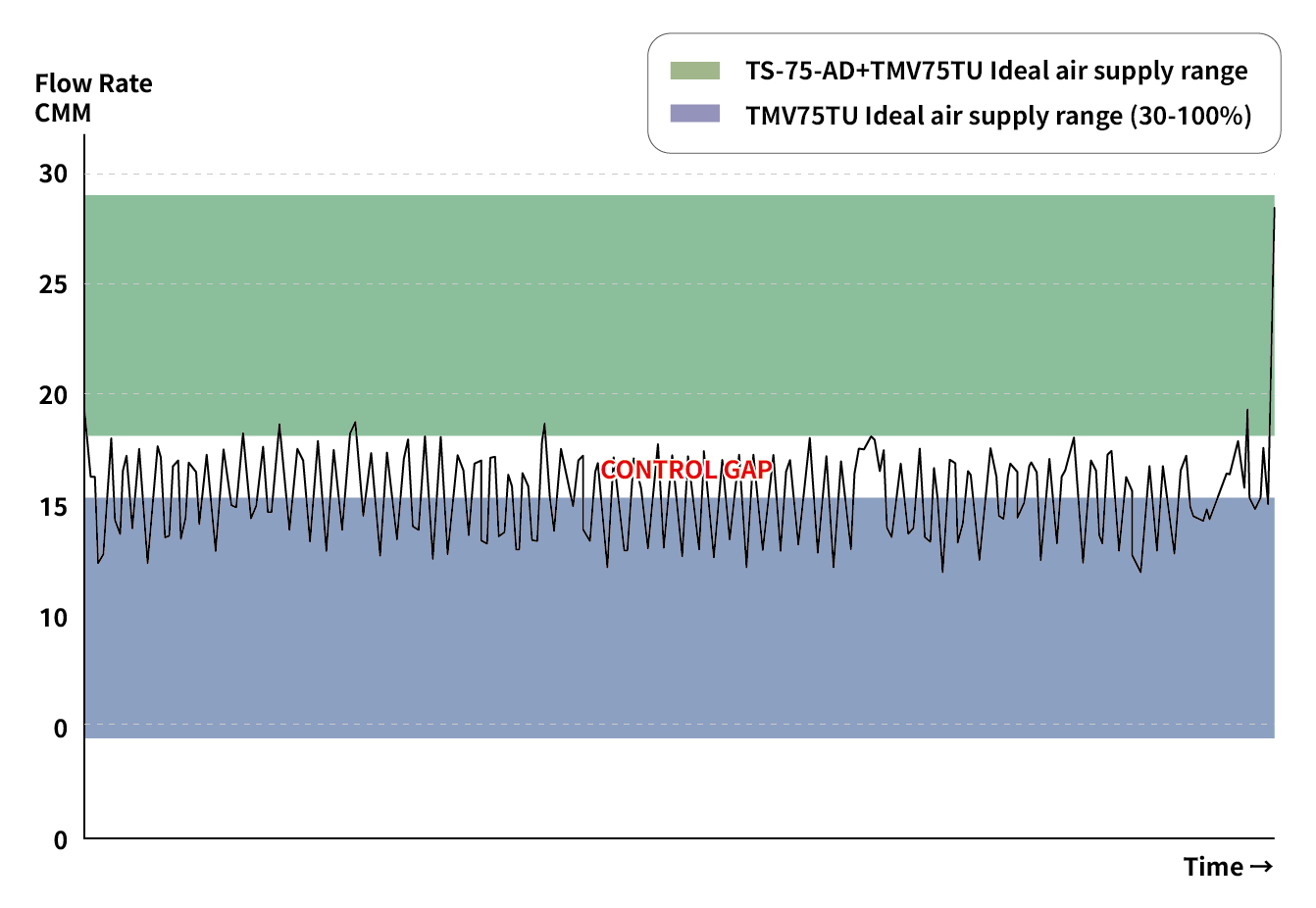

3. Control Gap Generated

Control gap happens when the supply of compressed air cannot meet the demand effectively, resulting in excessive pressure fluctuations, energy consumption, and system instability.

How does the control gap occur?

- Improper Configuration:

When the variable frequency air compressor runs at full loading and the fixed frequency air compressor as a regulator, the first machine loses its advantage of speed regulation. The fixed frequency air compressor will also start and stop loading frequently to adjust capacity, which leads to excessive pressure fluctuations and increased mechanical wearing.

- Compressed Air Demand Fluctuates:

Air demand drastically increases during peak period and drops sharply during off-peak. If the air compressor system cannot adjust air consumption in time, it will lead to unstable pressure and the control gap happens.

Take the figure above as an example: the air capacity of TMV75T is about 5~16 CMM, and 13 CMM for TS-75-AD. When both units operate simultaneously, the air capacity is 18~29 CMM. When the air demand is 16~18 CMM, the TMV75T alone is insufficient and will trigger the fixed frequency air compressor to start operation. When both units operate, the air supply is higher than the system demands. As a result, the control gap happens and the air compressor will run in unloading condition, which defeats the purpose of the inverter control.

Topic 2: Operation mode of variable frequency air compressor

The advantage of variable frequency air compressors is to adjust the motor speed with variable frequency-controlled technology according to the air demand. The traditional fixed-frequency air compressor is more efficient only during fully loading operation. The efficiency will drop significantly at the minimum loading conditions resulting in increased energy consumption.

The variable frequency drive (VFD) is the core component of the variable frequency air compressor. Using real-time data feedback from the pressure sensor, it adjusts the operating frequency of the air compressor to maintain the pressure at the set range to reduce energy consumption, minimize air end wear, and extend the overall machine lifespan.

Operation settings of variable frequency screw air compressor

A. Mandatory operating parameters of the variable frequency air compressor:

2. Unloading Pressure: the air compressor will unload when the pressure reaches the pre-set value.

3. Loading Pressure: the air compressor will load and operate with heavy loading when the pressure drops to the pre-set value.

*When the air demand is higher than the air supplied at full speed, the pressure will be lower than the target pressure value due to insufficient air supply.

*When the air demand is lower than the air supplied at minimum speed, the pressure will gradually increase from the target pressure value.

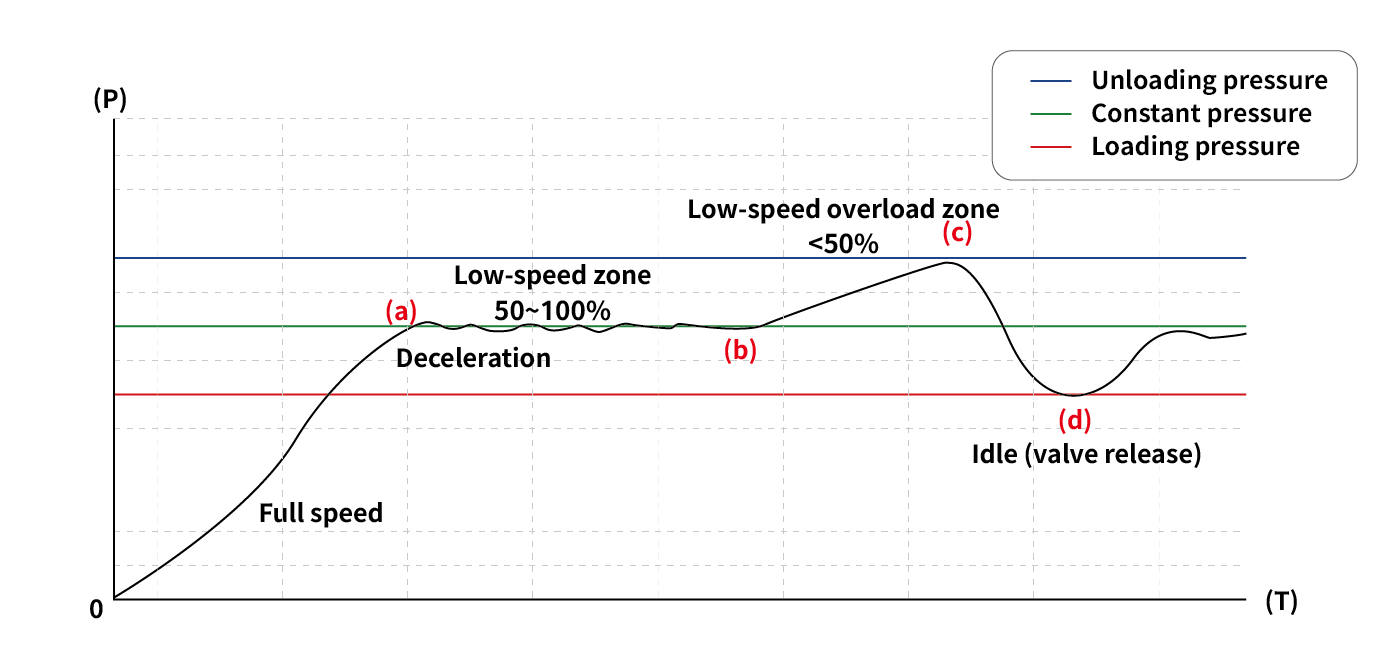

B. The variable frequency screw is not in full speed control:

1.Traditional induction motor: the speed range is usually around 50~100%.

2.Permanent magnet drive air compressor: the speed range is usually around 30~100% or 40~100% depending on different adjusting concepts.

C. Air compressor operating analysis:

.jpg)

(b)~(c):The minimum loading is still over demand and the pressure gradually increases as excess supply accumulates.

When the unloading pressure value is reached with the lowest speed, the air compressor will idle and stop to supply compressed air. When the inverter idled, the system pressure drops to the load pressure (d) before the air compressor starts loading to supply air.

Topic 3: What's the most ideal configuration for a variable frequency air compressor to run at the optimal performance?

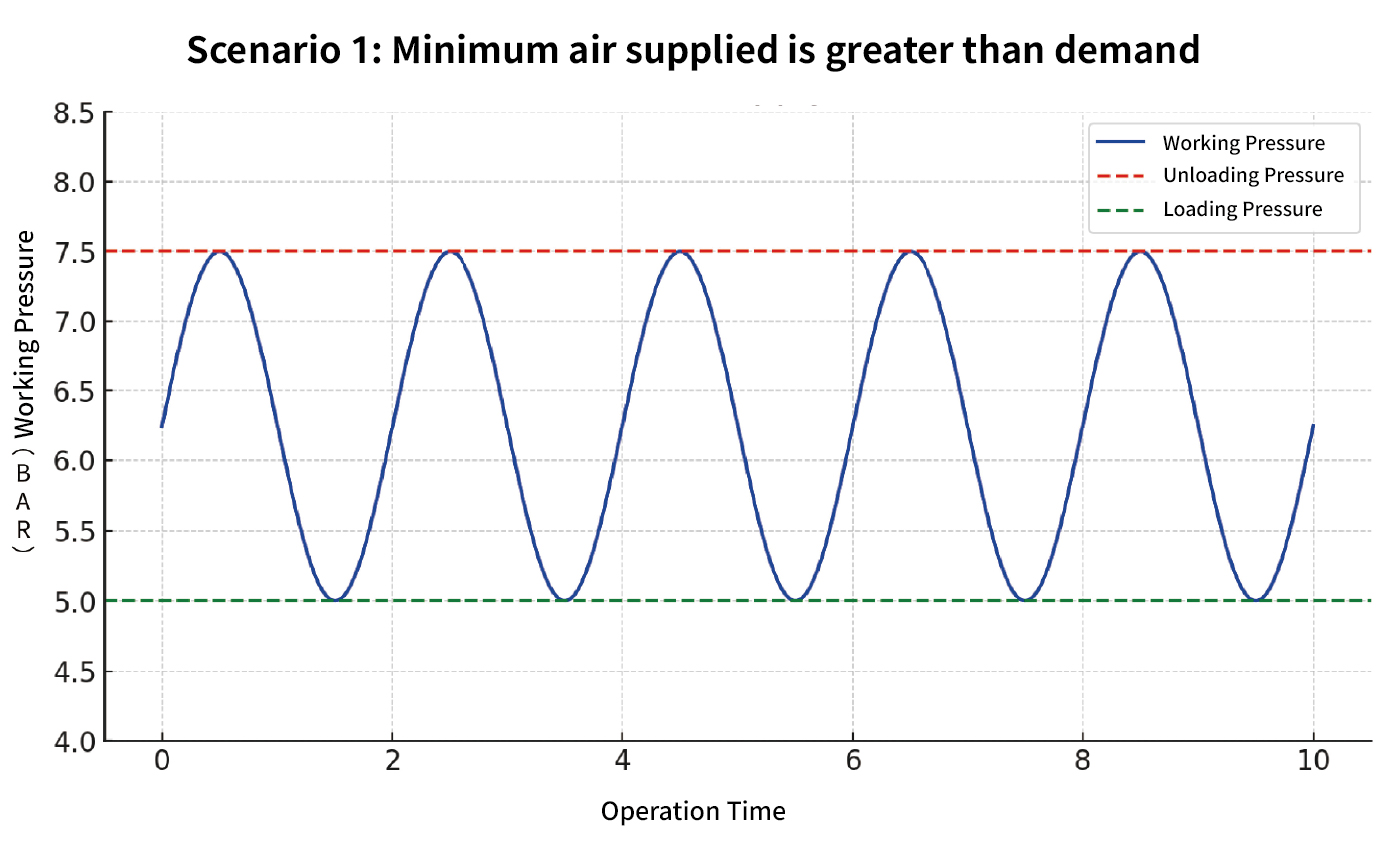

Scenario 1: Understand setting and capacity demand

When air supplied is greater than the demand, the system pressure will fluctuate between the unloading and loading pressure frequently. The gap between unloading and loading pressure is the result of wasting energy.

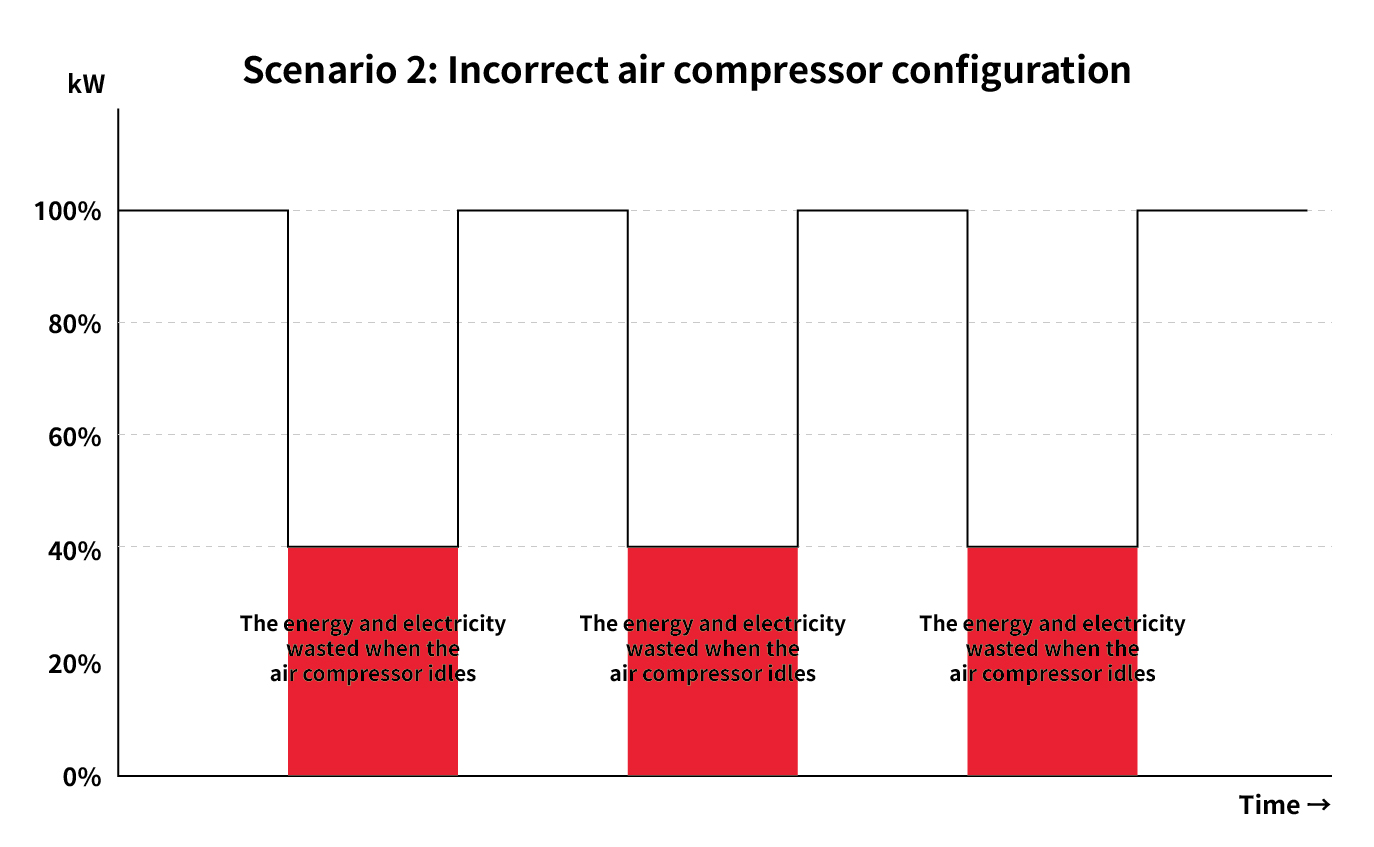

Scenario 2: Variable frequency model runs fully loaded and fixed speed model is used to adjust peak/off peak air supply.

When a variable frequency model runs at full speed, the unit cannot make adjustments as needed, leading to frequent unloading and loading and closing of air intake valves, which consumes additional electricity and wastes energy.

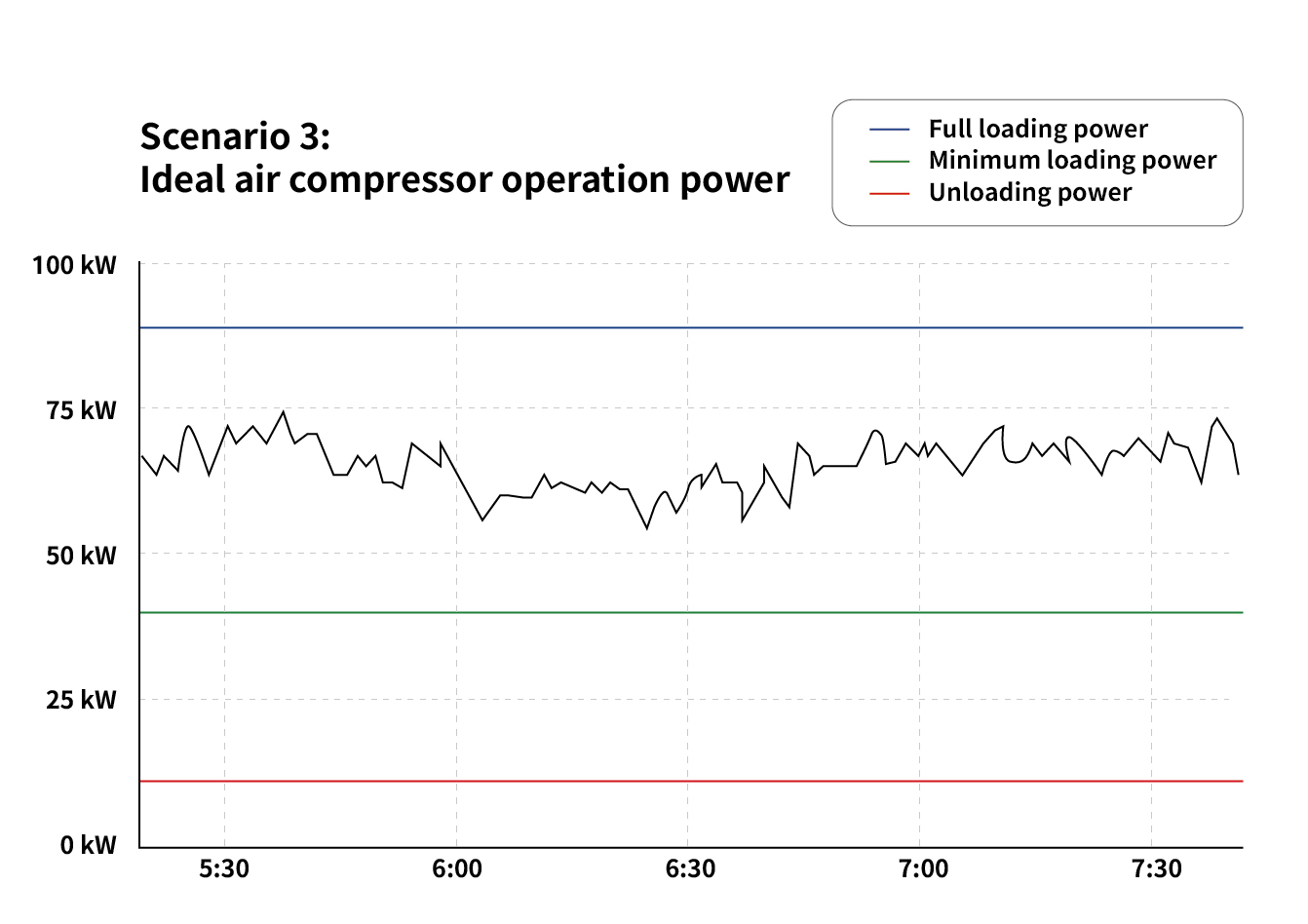

Scenario 3: Ideal configuration and setting

Air compressor supplies according to the demand and operates stably, without frequent unloading and loading and achieve optimal utilization.

Conclusion

Variable frequency air compressors have great energy-saving potential. However, improper model selection and configuration may dismantle that potential and lead to increased energy consumption, machine wear and tear, and unstable production.

.jpg)